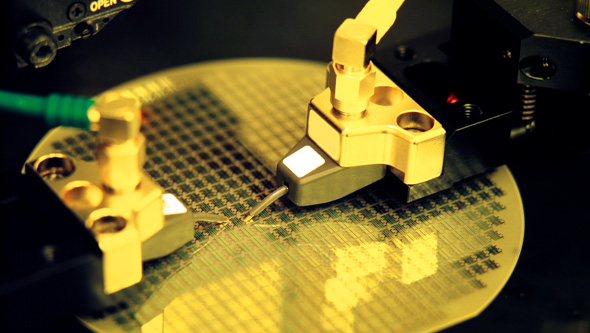

Semiconductor & Electronic Assembly

Innovation cycles in the semiconductor industry tend to be extremely short. According to Moore’s law, the complexity of integrated circuits doubles every 12 to 24 months. To facilitate further miniaturization, however, totally new manufacturing technologies are unavoidable. The highest possible precision is a vital prerequisite here. This is just as true for repeatability and positioning accuracy as it is for the ability to control even the smallest movements. Reliability and productivity are other crucially important aspects. Production often takes place in a cleanroom environment (up to cleanroom class ISO 6 as a minimum) – and increasingly also in vacuum (up to 10 or 12 mbar operating pressure in the meantime). The drives must be designed as compact as possible owing to the mounting situation. We offer solutions combining extreme power density, high dynamics and precision. Our drives provide optimal synchronous running – even in vacuum environments, leading to significantly higher throughputs.